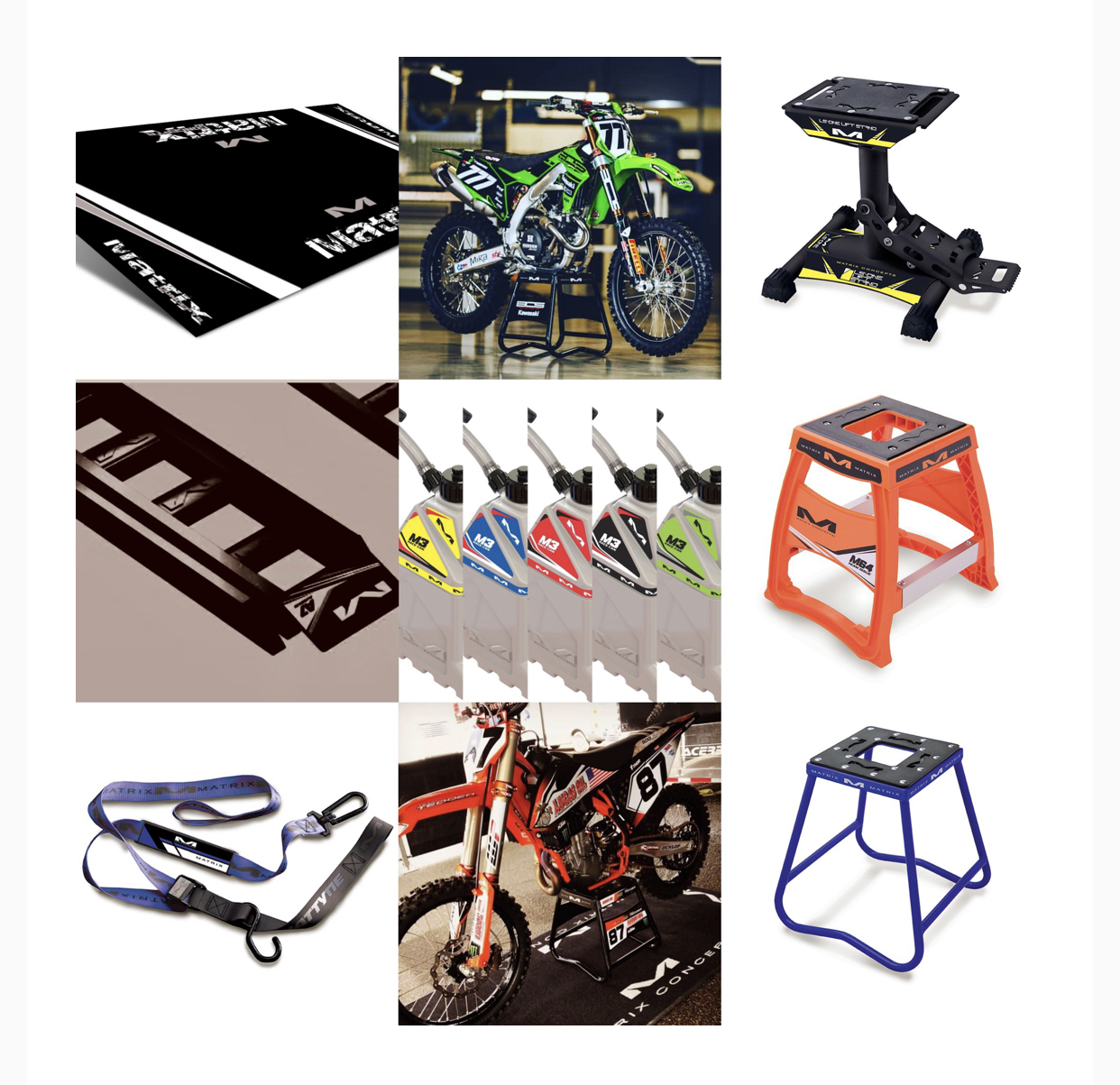

MATRIX CONCEPTS DESIGN, TESTING & MANUFACTURING

21st Sep 2019

Every MATRIX CONCEPTS product starts with a collaboration between our in house product management team, our professional athletes, professional mechanics and team managers.

The first step in our product development process is our IPAA (internal product assessment analysis) and market stress test. If approved products are assigned to a design team.

100% of our products are designed and engineered here in United States by either our in house designers or a dedicated team of engineer consultants.

After the design phase is completed products go through a rapid prototype or SLA process to confirm the design meets all the product and end users requirements. Teams and riders confirm the design and durability.

Next production tooling is finalized. First production articles are produced and go through a stringent testing protocol by the top teams and rider/ mechanics in the world of racing. After performance confirmation the product is released for production.

All of our manufacturers go through a strict venting process and are confirmed with our on-site factory visits.

All of our factories have a quality assurance program in place and comply with all local laws & international standards.

Our factories are dedicated to producing and delivering the very best products.

MATRIX CONCEPTS | DESIGN DRIVEN